Do you still have trouble finding a reliable smart watch supplier? Are you afraid of the factory being unable to ship on time when the delivery date is reached? Or are you worried about the vast differences between the finished product and the sample?

Experienced and professional suppliers can provide smart watches with guaranteed quality and delivery. They can also make good suggestions and help optimize production. In addition, they can significantly save your production cost while producing high-quality smartwatches.

Today I will tell you the secrets of the OEM smartwatch industry. It takes only 8 steps to customize an OEM smart watch in China quickly. So let me walk you through it step by step.

Define Your Smart Watch

Before sourcing the ideal supplier for your smartwatch, it’s important to take time to identify basic needs and requirements. First, you’ll need to determine your desired features and functions for the smartwatch. Next, don’t forget the specific requirements for materials, parts, or manufacturing processes. All these aspects play an integral role in crafting your desired finished product.

You can conduct market research first if you are new to the industry. Research the demand for smart watches in the target market, including the audience of smartwatches, competitive brands in the market, popular styles, materials, functions, etc.

You can also consult the Starmax professional team directly. We are a Chinese OEM smart watch supplier with over 7 years of experience crafting top-quality, cost-effective smartwatches. Our product lines include smartwatches, sports bracelets, data monitoring equipment, and home-connected devices.

Select the Place of Production

The production of smart watches of different origins will affect their value for different reasons, and the production of the same product in different countries will show different values. These reasons include the product’s cost, quality, brand image, and consumer preferences.

For instance, consumers may associate the quality of a smartwatch with its country of origin. They will likely assume that the country’s industrial reputation and the technology used in smartwatch manufacturing directly affect its quality.

Shenzhen, China, is your best choice if you are looking for quality and cost-efficient smartwatches. It is known for its strong manufacturing and service industries and consistently ranks highly on China’s industrial output index. In addition, its supply chain streamlines provide competitive prices on raw materials while ensuring fast delivery through its extensive transport networks.

With headquarters in Shenzhen, the leading innovation hub of technology development, Starmax offers top-notch technical support and lightning-fast supply chain services.

We set up a manufacturing center in Dongguan, covering 8 automated production lines, producing product motherboards, and assembling straps and packaging. We have a production workshop of more than 6000 square meters and over 320 production and warehousing workers.

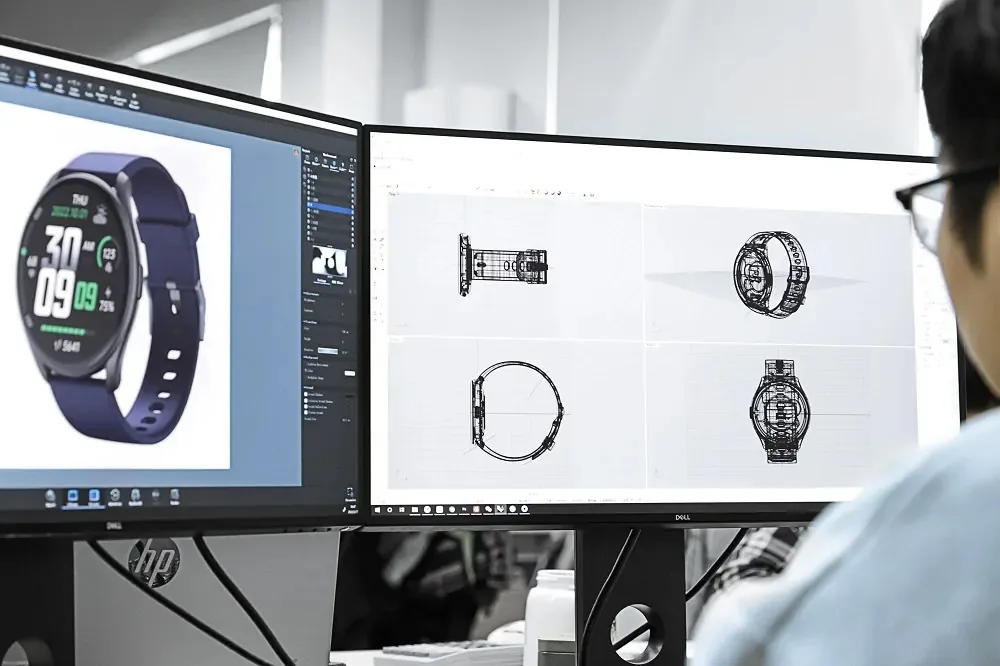

Design and Develop A Prototype

The first step in the production process is designing and developing a smartwatch prototype. It includes everything from selecting the right display technology to deciding the type of sensors you want in your smartwatch.

Smartwatches are a combination of various hardware and software solutions, each with its specific purpose. The software enables it to connect to the internet, monitor fitness stats, notify users, and so on. Hardware parts such as sensors and displays allow smartwatches to collect data about your physical state and display it efficiently.

To develop a prototype, the design team must create detailed drawings and specifications for each watch element. This process typically entails creating a 3D model of the device, mapping all its parts, and simulating how they will work together. Once this is done, it’s time to build a physical prototype for testing in the field.

Starmax has demonstrated strength in multiple R&D branches, from firmware engineering services to APP development, especially in developing sports data management and health monitoring software. Our R&D team is well-equipped and can provide superior hardware & software integration solutions.

Finalize Raw Materials

After the design phase of a smartwatch, the next step is to source the materials and parts used in the production process. These may range from essential elements like plastics and metals to sophisticated electronics such as sensors and displays.

The most important criteria to ensure quality and reliability are material selection, performance requirements, availability, and compliance with laws and regulations. With these supplies, your next step is ready for smartwatch assembly.

Starmax provides superior products and services at affordable prices. Our expert procurement team assesses each raw material supplier, guaranteeing they fulfill our stringent delivery specifications and follow all relevant regulations.

By selectively choosing suppliers with high-quality goods at competitive prices, we can deliver the best possible value for your money.

Test and Send Sample

After the smartwatch prototype is assembled, this sample will soon be sent to quality control departments for rigorous testing, usually measuring accuracy, durability, comfort, and usability.

After testing the prototype and making any modifications, you’ll have a finished design and production specifications. You can then get an actual sample of the smartwatch. Or the factory will send a detailed function and quality demonstration video before mass production.

Starmax has design, hardware, firmware, mobile application, and professional inspection teams, providing first-class solutions and services to meet your needs. Entrusted us with your smartwatch development from concept to production, you can rest assured knowing that experts in each field can assist you.

Get Certified

After the smartwatch sample is delivered and the final confirmation is completed, the next step is to certify. Depending on the country or region, different certificates will be required to ensure that our product meets safety requirements. Possession of these qualifications is critical for market access and customer satisfaction.

Starmax’s smartwatches come with the necessary certificates, and we can assist you in obtaining the additional certificates you need. In addition, we carry out strict monitoring and inspection during the production process to ensure that the products are qualified, and the quality is guaranteed.

Prepare for Mass Production

Before proceeding to mass production, the necessary equipment and facilities for manufacturing processes, such as machines and instruments, must be ready.

To ensure a flawless result, the factory will conduct trial production to ensure efficient, effective, and high-quality full-scale production. In addition, the factory will adjust materials and equipment as needed throughout this process to provide qualified and satisfying products.

Starmax has a dedicated manufacturing plant with advanced equipment, and more than 320 factory employees can fully meet your delivery needs. In addition, 7 years of smartwatch manufacturing expertise has helped us form a quality control system that meets global standards. Our team of trained professionals follows strict processes to ensure all products meet the highest level of consistency and accuracy.

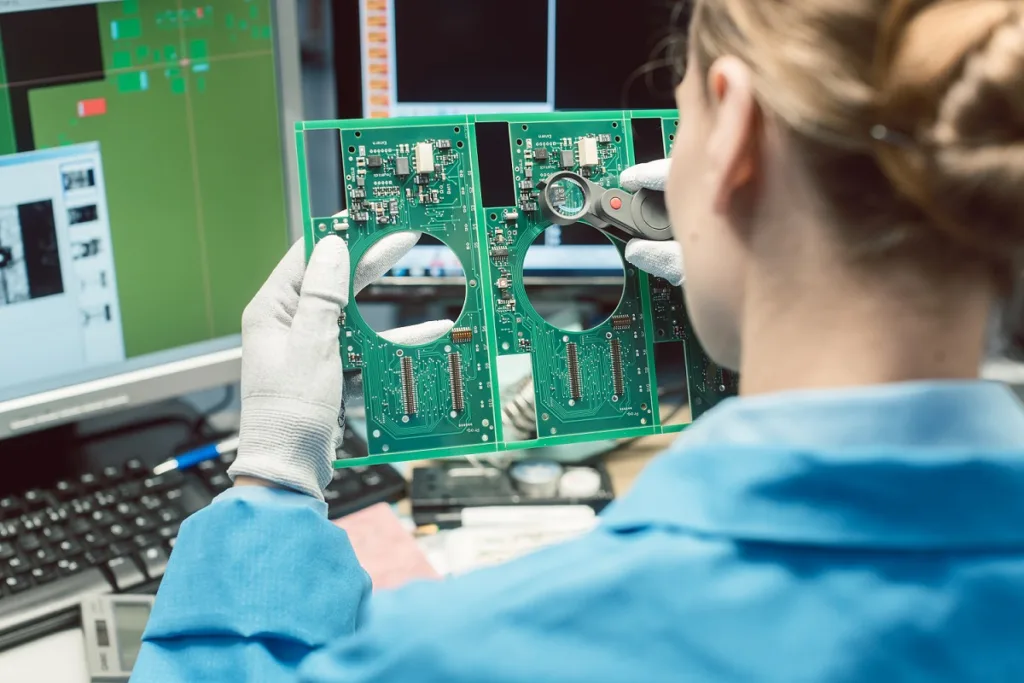

Make Quality Inspection Before Delivery

Once the smartwatches are assembled, there will be a final quality inspection before packing and shipping. The inspections may include functional testing, durability testing, water resistance testing, and others.

This procedure ensures that all smartwatches meet all necessary quality and performance standards and helps ensure that all consumers receive a product that meets or exceeds their expectations. In addition, Smartwatch manufacturers typically keep complete records of all testing procedures for quality assurance and legal compliance purposes.

Once the smartwatches have been rigorously tested and approved, they are ready to be shipped out. Each smart watch should include all necessary packaging materials, their respective charging accessory for use, a user manual, and the smartwatch itself.

At Starmax, we are committed to upholding the highest levels of quality and safety. Our company is ISO 9001, and BSCI certified, ensuring every production step is monitored to the highest standard. Additionally, our products comply with all necessary certifications, such as CE, FCC, BIS, Bluetooth Alliance, Japan Radio Certification, and RoHS.

Conclusion

The production process of a smartwatch involves many steps, possibly involving various team members and experts. However, by following these tips, you can find a reliable OEM smartwatch manufacturer who can make a smartwatch that meets your needs.

Remember that we will produce products strictly according to the technical standards and technological processes you require. Not only that, all our employees involved in production will keep your core technology confidential.

Starmax provides you with professional solutions. If you want to visit our company and factory, please be sure to get in touch with our team.