Visit Starmax Factory

Facts and Strengths

Engage in Whole Procedure

100% Material Pass Rate

Strict Production Rules

Skilled & Trained Staff

ISO 9001 Certified Management

Safe Storage & Shipping

Key Metrics of the Factory

8

Production Lines

320+

Factory Staff

6,000+

㎡ Factory and Storage

10M+

Annual Production Capacity

ISO9001

Certified by ISO

BSCI

Certified by amfori

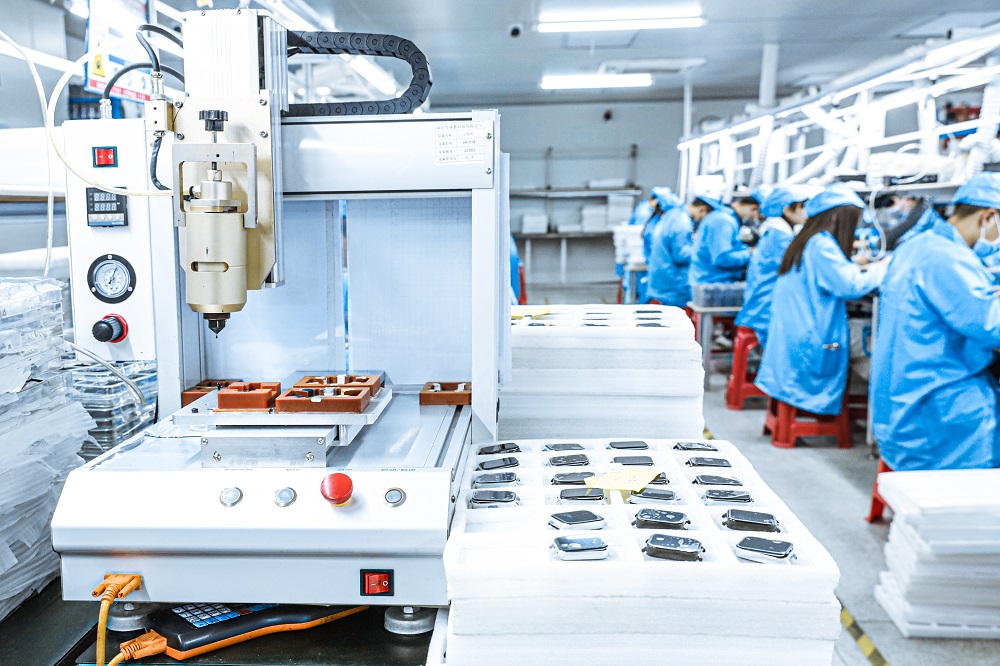

Our Factory

Starmax factory is located in Tangxia Town, Dongguan City – the heart of the Greater Bay Area in Southern China. Our factory currently has 6,000 square meters of production and storage zone, involved in the whole process of smart bracelet manufacturing, from PCB placement – assembly – testing – packaging to delivery of the one-stop solution. We have 6 production lines, 320+ factory staff. Our factory capacity is up to 10 million pieces per year. Starmax is also ISO9001 certified, and BSCI social responsibility audit passed. We work with many International retailers and buyers.

Assemble, Pack, and Quality Control

AUTOMATED PRODUCTION

SMT Lines

Our factory is ISO 9001 compliant. This picture shows one of our SMT lines. SMT is used to manufacture PCB circuit boards, which are the heart of a smart watch. Our SMT production pass rate is higher than 99.5%, which is the advanced level in the industry.

AUTOMATED PRODUCTION

Assembling

The circuit board manufactured by the SMT production line will be embedded into the housing of the watch or bracelet, this small piece of watch, integrated with a pedometer, heart rate sensor, blood oxygen sensor, and other advanced components.

QUALITY CHECK

Water Resistance Test

The air leak machine is used to test the water resistance reliability, placing the product in a vacuum environment and extracting air from it, in order to test if it meets the waterproof level.

QUALITY CHECK

Charging Test

In this step, our quality control team will test each smartwatch for charging, so that we can confirm that the battery and charging of all products can work properly. We use high-quality lithium batteries that can reach up to 1000 times charge and discharge, enough to support more than 3 years.

QUALITY CHECK

Display Test

The display is one of the most important components in the entire smartwatch. We pursue the highest standard of quality control, using both machine and manual testing to ensure that each product’s display is stable, colorful, and free of bad dots.

PACKAGE

Auto Packing

We use a fully automatic packaging system, which ensures close to 100% packaging accuracy, and this packaging system also adds blister film to the boxes to prevent damage due to moisture in the storage and transportation of the product.

PACKAGE

Pack & Ship

Now the product is ready for ship, our QC team will make a final check on package and carton, to make sure it is all correct.

OEM or ODM Inquiry

Reserve Onsite Inspection

- Please use the form to let us know details about what you need.

- We will reply in 1 day.

- After filling out the form, you will be redirected to the catalog download page.

Book a Meeting, Let's talk

Let’s talk directly. Call with our expert sales team to discuss your project. (Meetings take place in English)