In today’s tech-savvy world, smartwatches have revolutionized the way we live, work, and stay connected. Beyond just telling time, smartwatches can help monitor health, schedule tasks, track fitness, and even integrate with smartphones for various applications. Venturing into or excelling in the smartwatch industry requires a blend of innovation, quality assurance, and market insights.

Understanding the smartwatch production process is vital for sourcing companies, e-commerce sellers, and retailers to ensure product quality, optimize supply chain efficiency, and cater to evolving consumer demands, strengthening their market position and fostering trust among tech-savvy consumers. This comprehensive guide will take you on a journey through the various stages of smartwatch manufacturing at the Starmax factory, revealing the process that brings these innovative products to life.

Smartwatch Manufacturing Process at the Starmax Factory

1. Design and Prototyping

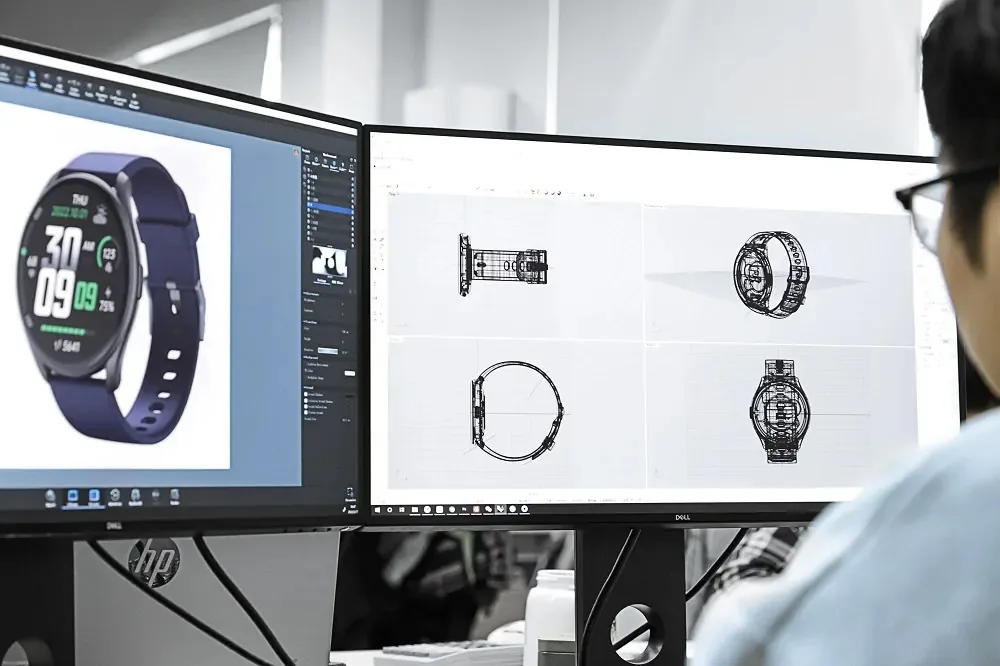

The smartwatch production journey at Starmax kicks off with conceptualization and design. Starmax‘s skilled designers and engineers collaborate to draft the smartwatch’s blueprint, focusing on aesthetics, functionality, and technical specifications.

Starmax’s product line covers smartwatches, fitness trackers, and kid smart bands, including the hot-selling GTS5 smart watch with Bluetooth Calling and the latest S5 4th Generation fitness tracker. Informed by extensive market research, our designs not only align with current consumer trends but also meet stringent safety and environmental standards. Additionally, we offer basic customization options including personalized strap color and logo engraving.

Once the design is finalized, a prototype will be created for testing and evaluation. A prototype, crafted through methods like 3D printing or CNC machining, brings this vision to life. This phase is critical for rigorous quality assurance and user experience optimization, verifying the design’s feasibility and functionality, and alignment with both manufacturer and consumer expectations.

2. Component Sourcing

After finalizing the design, Starmax starts sourcing the necessary components. These components include the watch case, display, battery, sensors, PCB, and various other electronic components.

Ensuring premium quality in these components is essential to the reliability and performance of the final product. Recognizing the significance of this stage, most procurement entities pay more attention here. Starmax’s partnerships with elite raw material suppliers underpin our commitment to smartwatch longevity and functionality. So, collaborations with trusted smartwatch suppliers, like Starmax, help your business remain future-ready and resilient.

3. PCB Assembly

Once the materials have been sourced, the smartwatch manufacturing process begins. The core of the smartwatch is its PCB, where all electronic components are integrated. PCB assembly involves soldering and connecting these components to create a functional circuit board. At this stage, precision and attention to detail are crucial to prevent defects and keep the smartwatch’s proper functioning.

Starmax factory is equipped with cutting-edge machinery and a skilled workforce to seamlessly assemble everything from processors to displays. Rigorous quality control is upheld at each stage.

Once the PCB, sensors, and battery integrate, they’re encased, topped with a display, completing the smartwatch’s form. The assembly, influenced by production scale and complexity, can be manual or automated, always requiring skilled workers, advanced machinery and strict quality control.

4. Software Development

Smartwatches, as miniature computers, demand specialized software for optimal performance. Starmax’s expert software developers meticulously design custom firmware and software to govern each smartwatch’s features, user interface, and connectivity. Starmax also offers App customization and SDK customization for bulk smartwatch orders, enriching the smartwatch experience and allowing for the personalization of branded OEM/ODM products. User-friendly interfaces and seamless connectivity with smartphones remain essential aspects of our software development.

5. Assembly and Testing

With the PCB and software in place, the smartwatch assembly process begins, including the watch case, PCB insertion, display attachment, and battery installation. Thorough testing follows, including functionality checks, water resistance testing, and quality control inspections. This stage helps identify and correct defective or erroneous units, thereby minimizing the chance of defects entering the market.

6. Quality Control

Quality control is an ongoing process throughout smartwatch production, reaffirming our commitment to delivering exceptional services and products to our business partners and end-users. Starmax conducts rigorous inspections to ensure that each unit meets the specified quality standards, including build quality, screen calibration, battery life, and overall performance.

Our quality assessment extends to the pre-delivery stage, before each finished smartwatch is delivered to a trader or distributor, to ensure they work properly and are free of defects or errors. Starmax factory implements comprehensive quality control measures to ensure better product quality and maintain your brand reputation.

7. Packaging and Branding

After successfully passing quality control, the smartwatches will be packaged and branded according to our client’s precise specifications. The packing list includes a smartwatch, its accessories, and user manuals. Packaging and manuals are designed to be attractive, informative and comply with labeling and safety regulations to ensure excellent product presentation.

At Starmax, we understand the vital role packaging plays in leaving a lasting impression. That’s why our smartwatches are beautifully packaged for retail and display. For retailers and e-commerce merchants seeking to make their mark, Starmax’s custom packaging design and personalized branding solutions are readily available, not only prioritizing product protection but also helping you establish a distinctive brand identity in the market.

8. Shipping and Logistics

The final step in the production procedure is shipping and logistics. Located in Dongguan, Guangdong, the Starmax factory benefits from this strategic location for rapid logistics. We collaborate with top-tier logistics partners to ensure safe and timely deliveries. We provide flexible global distribution options to cater to our customer’s diverse needs, ensuring exceptional service even during peak seasons like Black Friday and Christmas.

Why Choose a Reliable Smartwatch Factory

When considering a smartwatch factory, selecting a trusted partner is paramount in the wearable tech industry. Here are compelling reasons to collaborate with a reliable manufacturer like Starmax:

- Quality Assurance: At Starmax, we prioritize quality control at every stage of production, minimizing defects and ensuring customer satisfaction.

- Customization: Starmax offers extensive customization options, empowering businesses to craft unique smartwatches tailored to specific target markets.

- Cost Efficiency: Leveraging large-scale production and efficient supply chain management, Starmax can help businesses achieve cost savings, enhancing their market competitiveness.

- Technical Expertise: Starmax boasts extensive expertise in smartwatch technology, providing valuable guidance throughout the design and development phases.

- Reliable Supply: With our consistent production and on-time deliveries, you can rely on Starmax for a steady supply of smartwatches to meet market demands.

Conclusion

The production of smartwatches is a complex and meticulous process that involves careful planning, design, testing, and quality control. For sourcing companies, e-commerce sellers, smart wearables dealers, and retailers looking to offer innovative wearable technology to their customers, understanding the process and selecting a reliable manufacturing partner is essential. As a smartwatch manufacturer from China, we are proud of our commitment to provide high-quality products, help you enter or expand the industry, and provide innovative wearable technology solutions to consumers worldwide.

For details on MOQ, customization options, shipping schedules, payment terms, sample requests, or factory visits, please contact the Starmax sales team using the form below. Additionally, you can schedule an online meeting with our experienced team for further discussion on your project.